Unleashing Precision & Innovation: Discover Our Cutting-Edge Machines

At Advanced Marble and Granite, we house a state-of-the-art workshop equipped with an impressive array of advanced machines. Located in Meridian, our workshop is bustling day and night to bring your projects to life.

Free Consultations

Precision Installation Service

Over 40 Years of Experience

BACA Systems - Robo SawJet 2.0

Combining the power of a robust saw and the accuracy of waterjet technology, this cutting-edge machine empowers us to tackle even the most complex projects with ease. It enables us to cut through various materials with exceptional speed and accuracy, minimizing waste and maximizing efficiency.

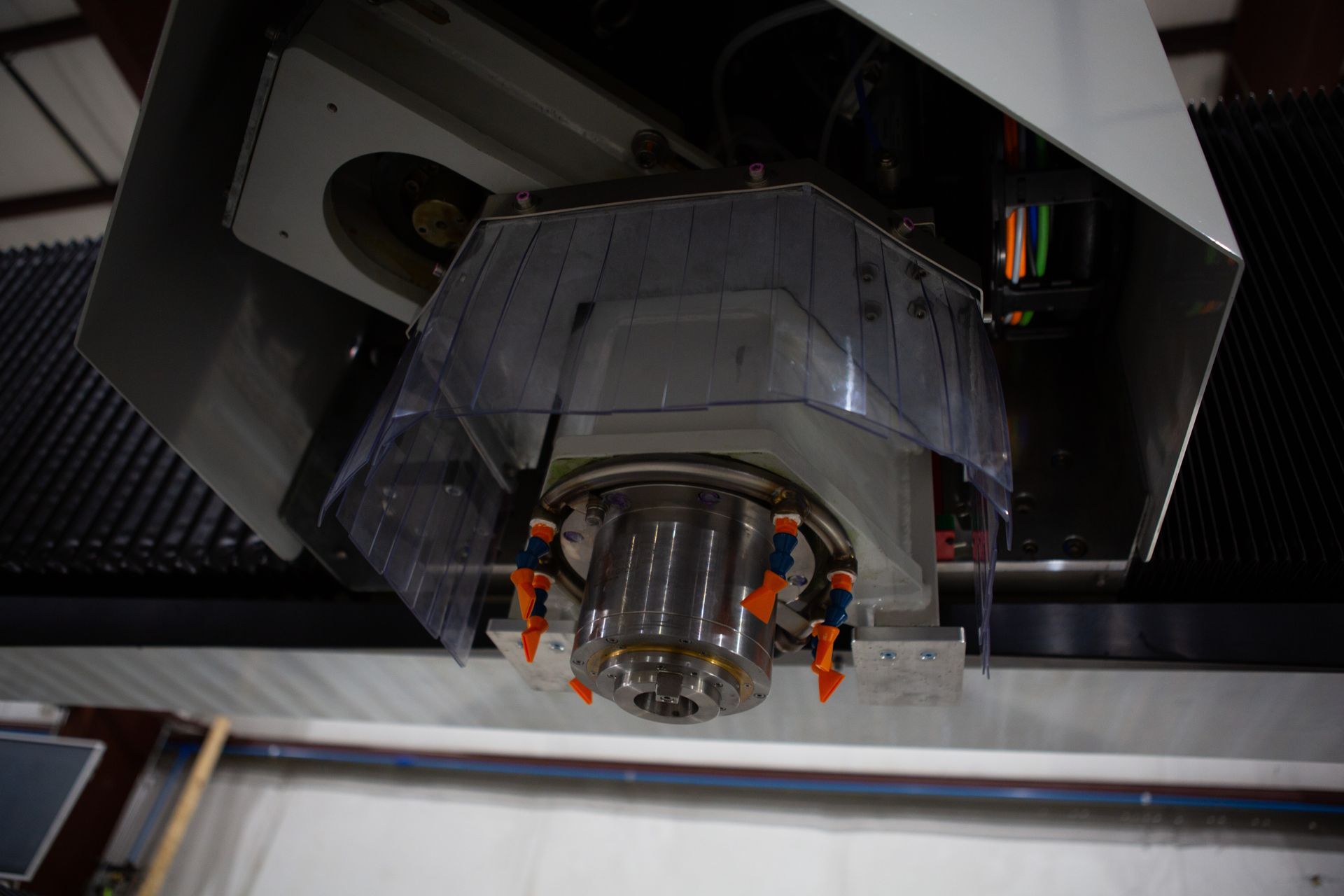

BBM - Paladin

These industry-leading workhorses embody precision and efficiency, allowing us to transform raw stone into stunning masterpieces. With their advanced features and cutting capabilities, the BBM Paladin machines ensure precise cuts, intricate detailing, and flawless finishes, resulting in unparalleled craftsmanship.

BACA - Robo SawJet 2.0

The water jet feature on the BACA Robot SawJet 2.0 offers several advantages. Firstly, it allows for precise cutting of a wide range of materials, including granite, marble, quartzite, porcelain, and more. The high-pressure water stream combined with the abrasive material enables clean and precise cuts, ensuring intricate detailing and complex shapes can be achieved with ease. Additionally, the water jet feature provides a smooth and polished finish on the cut edges, eliminating the need for additional polishing steps. This saves time and resources during the fabrication process, while still delivering exceptional quality and aesthetics.

Turrini DEP Water Recycling Systems

Turrini DEP Water Recycling Systems are renowned for their exceptional efficiency and effectiveness. They employ advanced technology to collect, filter, and recycle water used in our manufacturing processes. Each machine recycles approximately 7.2 million gallons per year. By reusing this water, we significantly reduce our consumption and minimize the strain on local water resources. These cutting-edge systems, manufactured by Turrini USA, play a vital role in our commitment to sustainability. By employing two of the 210 gallons per minute systems, we are able to save an incredible amount of water that would otherwise be wasted.

No Lift Install System

The award winning "No Lift" is a revolutionary install device that is transforming the way 2cm and 3cm granite and quartz counters are installed. The benefit to the installer is that the cart does the injury inducing lifts and rotations that shorten an installer's career. This also drastically reduces the risk of damage to the countertops, cabinetry and other property in the customers home. Additionally, it eliminates the common practice of sending "shop guys" to help put heavy and awkward counters in place. The cart lifts the counters to cabinet height using a remote control battery powered actuator. Then the counters are rotated safely into the horizontal position with the pivoting support frame. This frame has "transfer balls" that enable the counter to be easily slid onto the cabinet. Labor saving cranes, clamps, and vacuum lifters have been available for fabricators inside their stone shops for decades, and now with the No Lift Install System, the same help is finally available for their installers.

VISIT US at our NEW LOCATION

763 N. Ralstin St.

Meridian, ID 83642

HOURS

Mon-Fri: 9am-5pm

Sat & Sun: Closed

If picking up material, please do so prior to 2pm.

HOURS

CONTACT US

(208) 888-3844